Using computer numerical control (CNC) machining, manufacturers can complete three-dimensional cutting tasks with minimal effort. This important manufacturing process saves time, improves accuracy, increases worker safety, and boosts production volume. Depending on the type of material used and the complexity of the project, manufacturers may use CNC machines with multiple axes. It’s not uncommon to see 3 or 4 axis machines. While these machines provide a high level of precision for complex projects, better options exist. 5-axis machining enables machining of very complex parts, making it the ideal choice for aerospace, medical, and defense applications.

Using computer numerical control (CNC) machining, manufacturers can complete three-dimensional cutting tasks with minimal effort. This important manufacturing process saves time, improves accuracy, increases worker safety, and boosts production volume. Depending on the type of material used and the complexity of the project, manufacturers may use CNC machines with multiple axes. It’s not uncommon to see 3 or 4 axis machines. While these machines provide a high level of precision for complex projects, better options exist. 5-axis machining enables machining of very complex parts, making it the ideal choice for aerospace, medical, and defense applications.

About 5-Axis Machining

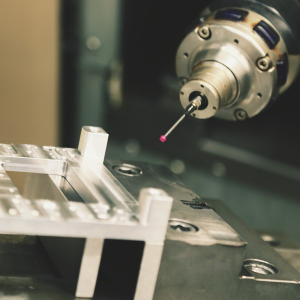

5-Axis CNC machines move linearly along the XYZ axes while rotating along two of them. Using multiple configurations, 5-axis machines produce parts with intricate designs quickly with no additional set-up. This allows manufacturers to increase production while eliminating the chance of error caused by multiple set-ups.

5-Axis Machining Benefits

5-axis machines use higher cutting speeds, significantly reducing the amount of time it takes to complete machining projects. Because these machines use shorter cutting tools, less load gets put on the cutter. This increases cutter lifespan and reduces the chance of breakage. The shorter tool causes less vibration, increasing the quality of surface finishing and eliminating the need for hand finishing for most projects.

Using a 5-axis machine, manufacturers can complete prototypes and small runs in less time at a fraction of the cost. What used to take months to complete can be finished in weeks, allowing new products to reach customers sooner and at a much lower price point than previously possible.

When using a 3-axis machine, manufacturers must use a different set-up for each hole. This takes a considerable amount of time and increases the chance of error with each new set-up. Using a 5-axis machine, manufacturers can simply orient the head along the correct axis automatically, reducing the time and effort spent drilling holes.

Produce Complex Parts and Products Quickly

Means Engineering recently acquired a 5-axis machine. Used to create extremely complex parts and products for the medical, defense, and aerospace industries, this machine will enable our team to develop prototypes and products faster and with greater accuracy. Our 5-axis machine enables machining of complex surfaces, shapes, and angles in a single set-up. This minimizes handling, reduces production time, and ensures consistent quality, even for large or repeated orders.

Please contact us for information about our machining services.