Electronics manufacturers must take necessary precautions to ensure nothing goes wrong with finished products. This is especially important for manufacturers creating devices for the medical, aerospace, and defense industries. Even devices made for other industries require careful assembly if manufacturers wish to avoid costly rebuilds, repairs, and recalls.

Electronics manufacturers must take necessary precautions to ensure nothing goes wrong with finished products. This is especially important for manufacturers creating devices for the medical, aerospace, and defense industries. Even devices made for other industries require careful assembly if manufacturers wish to avoid costly rebuilds, repairs, and recalls.

In order to ensure proper operation of all parts and components, electronics manufacturers must continuously test throughout production. Using a wide range of tests at different parts of the process helps ensure the quality and reliability of all finished products.

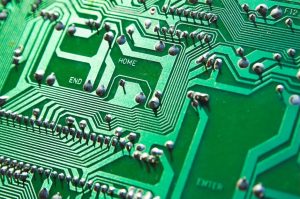

One of the most commonly used tests, in-circuit testing (ICT), helps ensure contract manufacturers and OEMs consistently meet defined parameters during production. ICT provides valuable information about problems with the board. This can prove extremely beneficial as most issues with electronic devices occur because of short circuits, wrong components, and open circuits on the board.

How it Works

ICT relies on a special test fixture, commonly referred to as “bed of nails” because it contains multiple contact pins. The contact pins come in contact with circuit nodes on the printed circuit board (PCB) to measure performance of the components. ICT allows contract manufacturers to measure various parameters including resistance, capacitance, and the operation of analog components. ICT is also sometimes used to measure functionality of digital circuits. However, full testing of circuit functionality isn’t usually feasible due to circuit complexity.

Benefits of ICT

When performed correctly, ICT can catch around 98% of faults with the board. Test results provided by ICT are easy to interpret. This makes it possible for manufacturers of all skillsets to locate problems quickly. Programming an in circuit tester is extremely easy. Electronics manufacturers can use information provided in the PCB layout to generate most of the program.

Disadvantages of ICT

Although ICT remains one of the most popular printed circuit board testing methods, it’s not without its disadvantages. As the size of components shrink, it’s becoming more difficult for manufacturers to gain access to all nodes on the board. This can lead to unreliable test results.

Contract manufacturers and OEMs must rely on a number of different testing methods to ensure the quality of finished products. This is especially important for those responsible for the creation of potentially life-saving products. Although ICT provides an effecting method for testing PCBs, it’s important that electronics manufacturers use additional tests to determine the quality and reliability of circuit boards.